MAGNETIC SENSORS SMC – SMP SERIES

WORKING PRINCIPLE

Magnetic proximity switches are made of reed contacts whose thin plates, trapped in a glass bulb together with inerted gas, are easily influenced by magnetic fields that create magnetic induction, opposite polarization.

Magnetic attraction force makes thin plates flex and touch each other causing an electrical contact. the plate’s surface has been treated with a special material particularly suitable for low current or high inductive circuits. magnetic sensors compared to traditional mechanical switches have the following advantage:

– Contacts are well protected against dust, oxidization and corrosion thanks to the hermetic glass bulb and inerted gas; contacts are activated by means of a magnetic field rather than mechanical parts.

– Special surface treatment of contacts assures in normal electrical conditions many of working cycles.

– Maintenance free, reduce encumbrance. The reed magnetic switches offer many electrical and mechanical characteristics together with various output functions.

– When in normally open (N.O.) mode the open reed contact closes as magnet approaches. They are supplied with two wires.

– When in the exchangeable (S) mode both N.O. an N.C. functions are made available by means of a single glass bulb. Placing the magnet close to or far from the reed switch activates the two different positions. They are supplied with three wires, one is in common, one is N.O. and one is N.C.

– In bistable function an internal magnet pre-polarizes the reed contact , but does not close them. Placing a magnet with the same polarity close to it the magnetic field is intensified, causing the contact to close, and remains that way even when the operating magnet moves away from the sensing area. The contact opens again when a magnet with opposite polarity, compared to the magnetic field, is placed close to it.

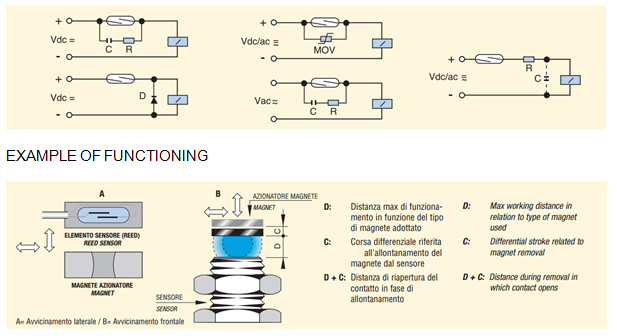

TYPICAL REED CONTACT PROTECTIONS

The lifespan of a magnetic sensor, at low values of tension and current, depends on the mechanical characteristics of the contact.

Whilst at high tension and current values it’s the characteristics of the load that influences the lifespan instead. In these cases it is suggestable to appliy some form of external protection at the sensors output.

BES M12MI-PSC40B-S04G

BES 516-325-S4-C

BES 516-3005-G-E5-C-S49

BES M08MI-PSC40B-S49G

BES M12MI-PSH80B-S04G

BOS 12M-PS-PR10-S4

BES 516-326-S4-C

BES M18ME1-PSC20F-S04G

BES 516-300-S135-S4-D

BES M08MG1-PSC60F-S49G

BES 516-300-S249-S4-D

BTL5-F-2814-1S

BCC06Z9

BCC06ZA

BES M08EC-PSC15B-S49G

BCC06ZC

BES M08MI-PSC20B-S49G

BES M08MH1-PSC20B-S04G

BES516-325-G-E5-C-S4

BES 516-324-G-E5-C-S49

BGL 120A-001-S49

BCC M425-0000-1A-003-PX0434-050

BGL 50 A-001-S49

BES 516-324-S49-C

BGL 30 A-001-S49

BCC M313-0000-10-001-PX0334-050

BES M18MI-PSC80B-S04G

BKS-S32M-00

BES 516-3005-E5-C-S49

BGL 80 A-001-S49

BES M12MI-PSC20B-S04G